12. Mai 2022

Today, we all know that servo presses are the best in terms of stroke rate and output. But what can be done when the production time is plenty to cover the demand of parts and at the same time the cost of materials and energy make any previous calculation obsolete?

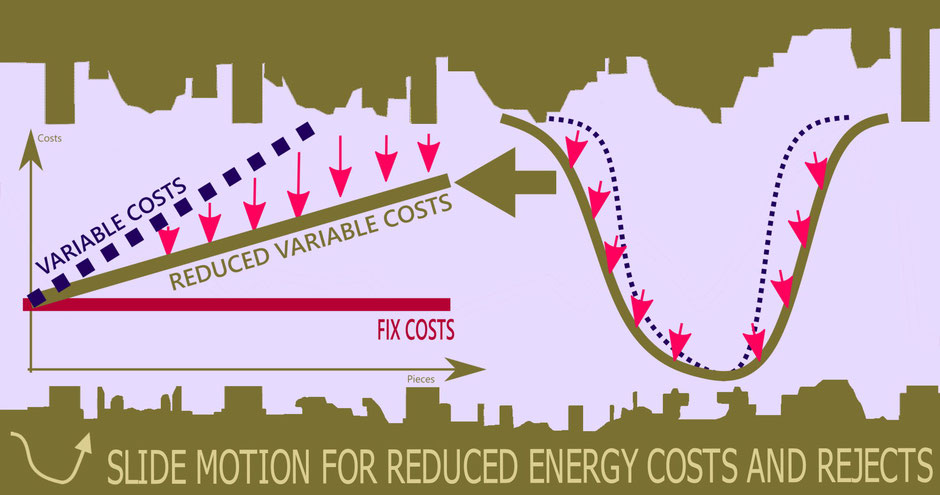

A slide curve adapted to current requirements significantly reduces variable costs. Instead of aiming for a high stroke rate, it is currently worthwhile to optimize the re-set-up in terms of reduced energy costs and fewer rejects.

10. November 2020

Finally there is a ray of hope - after day in, day out for months only one topic dominated our thinking. The pandemic not only dominates our private lives, we have also been fooled by the prevailing uncertainty in our business environment. At the latest now, with yesterday's news and the prospect of a vaccine, it is time to look ahead, define goals and prepare the stamping plants & forming machines for the post-COVID era.

05. April 2020

We are receiving dramatic pictures and messages these days.

But isolated glimmers of hope - as is currently the case at the petrol pumps - delight the consumer. And I am sure that just as the sun rises again after every night, we will overcome this crisis together.

Would you like to know how you can save on training in sheet metal forming?

Webinars for press setters provide basic knowledge for the optimal parameters of servo presses and/or for 3D / 3axis transfers.

25. März 2020

Social distancing? Low order volumes? What about the health of the loved ones? …?

A resource that is very rare in normal times - time - has been made available in the production environment.

Webinars offer an ideal opportunity to increase the knowledge of your employees while respecting the present ban on human contact. Use the time that has become free during these days without further interruptions in production, without affecting shift schedules to increase future productivity.

03. Januar 2020

The stroke rate of progressive and transfer presses can be significantly increased by the optimal adjustment of the process parameters. The success of such a process optimization is usually expressed by the increase in stroke rate.

But how much additional output must be achieved so that the costs of this effort can be economically justified?

21. November 2019

Whether you want to prepare yourself for the challenges that industry 4.0 / IoT or e.g. as a reaction to electromobility brings, there are many reasons why you want to recruit experts for your company. Providing know-how and expertise in new business fields or niche areas is always a challenge.

We also encounter these challenges in our everyday lives, even beyond the above-mentioned trendy and visionary directions.

21. November 2019

Egal ob Sie sich für die Herausforderungen, welche sich durch Industrie 4.0 / IoT oder z.B. infolge der Elektromobilität, wappnen wollen – Experten für sein Unternehmen gewinnen zu wollen hat vielerlei Beweggründe. Knowhow und Expertise in neuen Bereichen oder in Nischenbereichen vorzuhalten ist immer eine Herausforderung.

Diese begegnen uns auch im Alltag, auch abseits der oben genannten, trendy und visionären Marschrichtungen.

26. Oktober 2019

Great efforts are made to increase the production quantity of forming machines. Those responsible diligently create value stream analyzes, constantly optimize setting values, invest in modern production equipment and much more in order to increase output.

A concrete and outright structured analysis of the process bottleneck helps to address the causes with efficient means and leads to a sustainable improvement.

29. Mai 2019

State-of-the-art and high-performance stamping equipment in the press shop and yet the desired production volume is far from being achieved? ... or do you think a specific sheet metal component / tool should in principle achieve a higher output rate, even though it is much slower in real terms?

With the following easy-to-use tips, you can identify potential optimization potential for more stroke rate and ask your setup staff the right questions.